Introduction

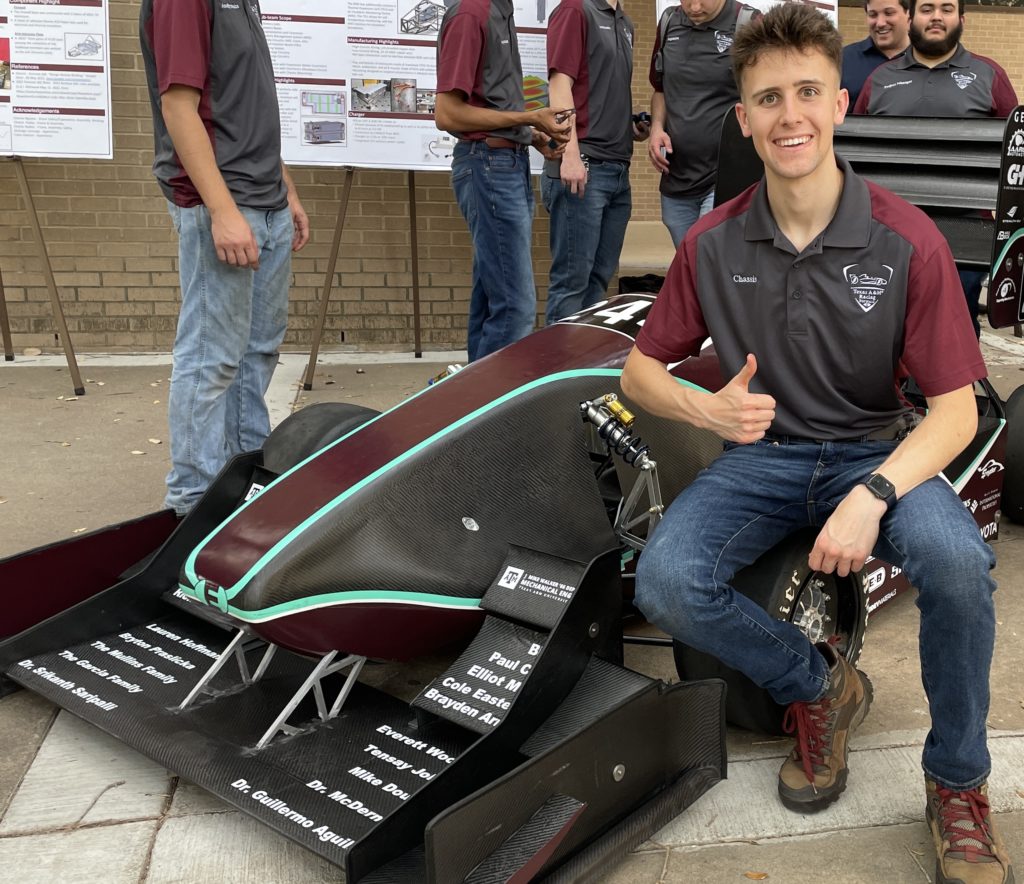

For my first season on an FSAE team, I was able to contribute as a chassis engineer. During that season, my subteam and I defined our engineering needs, made design choices accordingly, and successfully manufactured and validated our design through real-world testing.

Need Statement

“A readily adaptable, cost-effective chassis that will optimize rigidity and weight.”

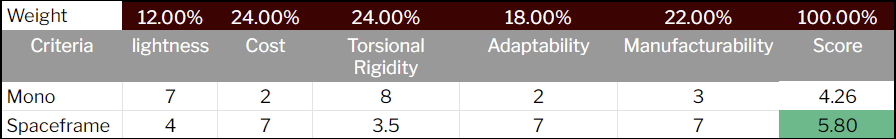

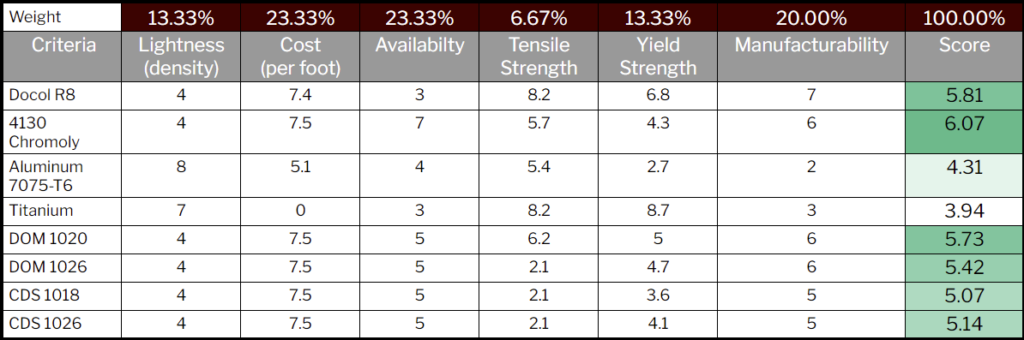

High-Level Design Choices

For the vehicle chassis, a few defining decisions had to be made at the beginning of the design cycle. These choices included the configuration and material.

Configuration: Spaceframe

Material: 4130 Chromoly Steel

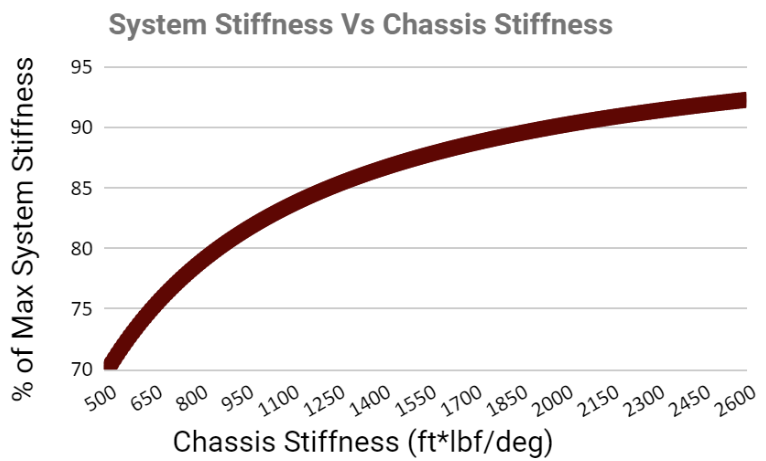

Torsional Rigidity

As seen in the plot, there is a point of marginal returns where it is not necessary to increase the chassis stiffness further. This occurs around 90% of full vehicle stiffness or 1960 lb*ft/deg chassis stiffness, which was chosen as our rigidity goal.

Manufacturing and Validation

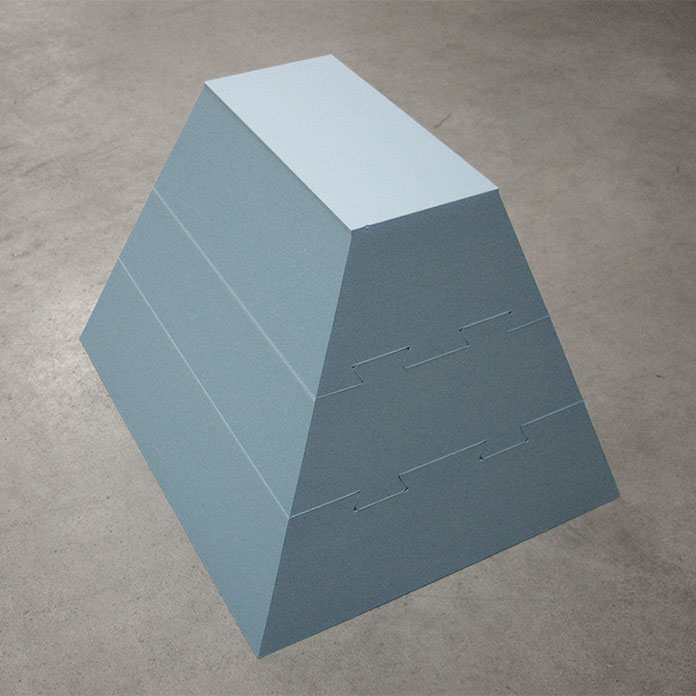

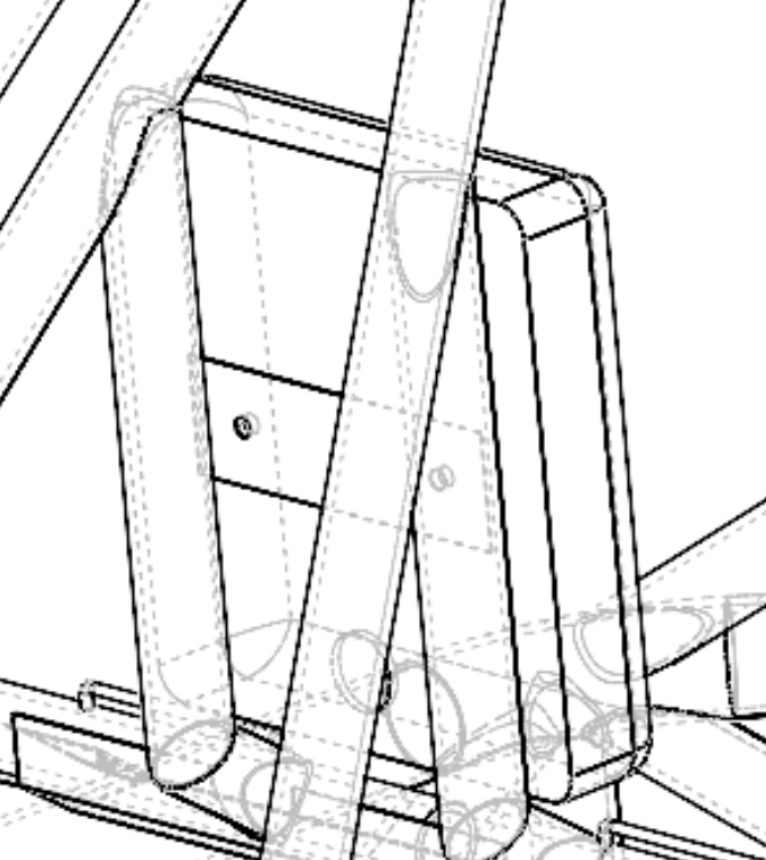

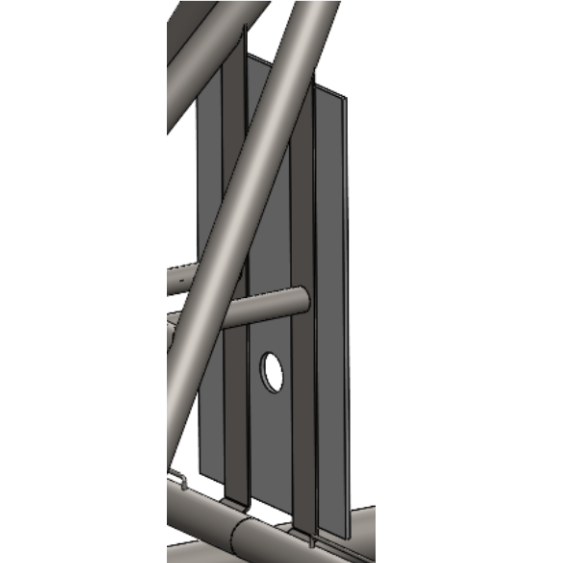

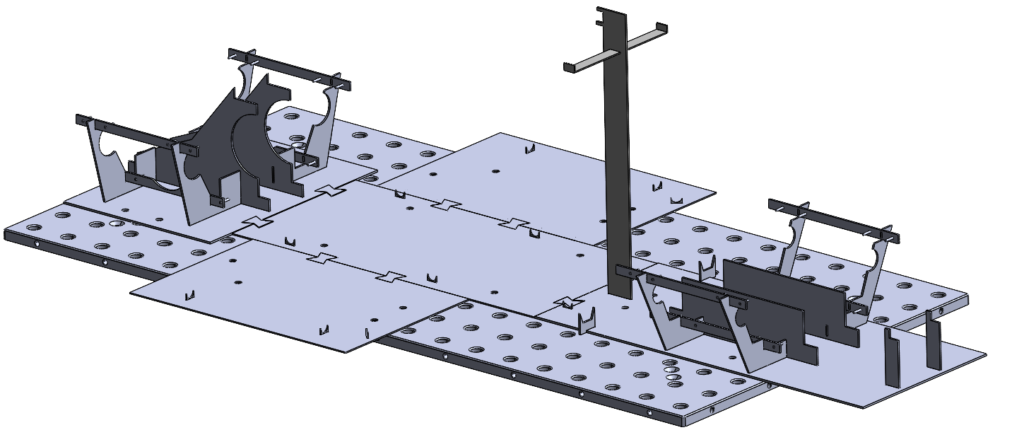

Welding Jig.

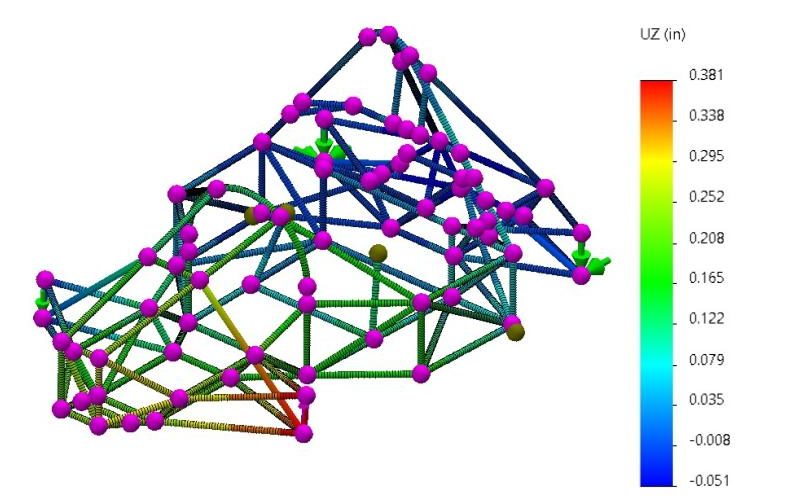

Simulation Validation

Physical testing gave a torsional rigidity of 2307 ft*lb/deg, representing only a 2% error from the simulation’s prediction.

Outcomes

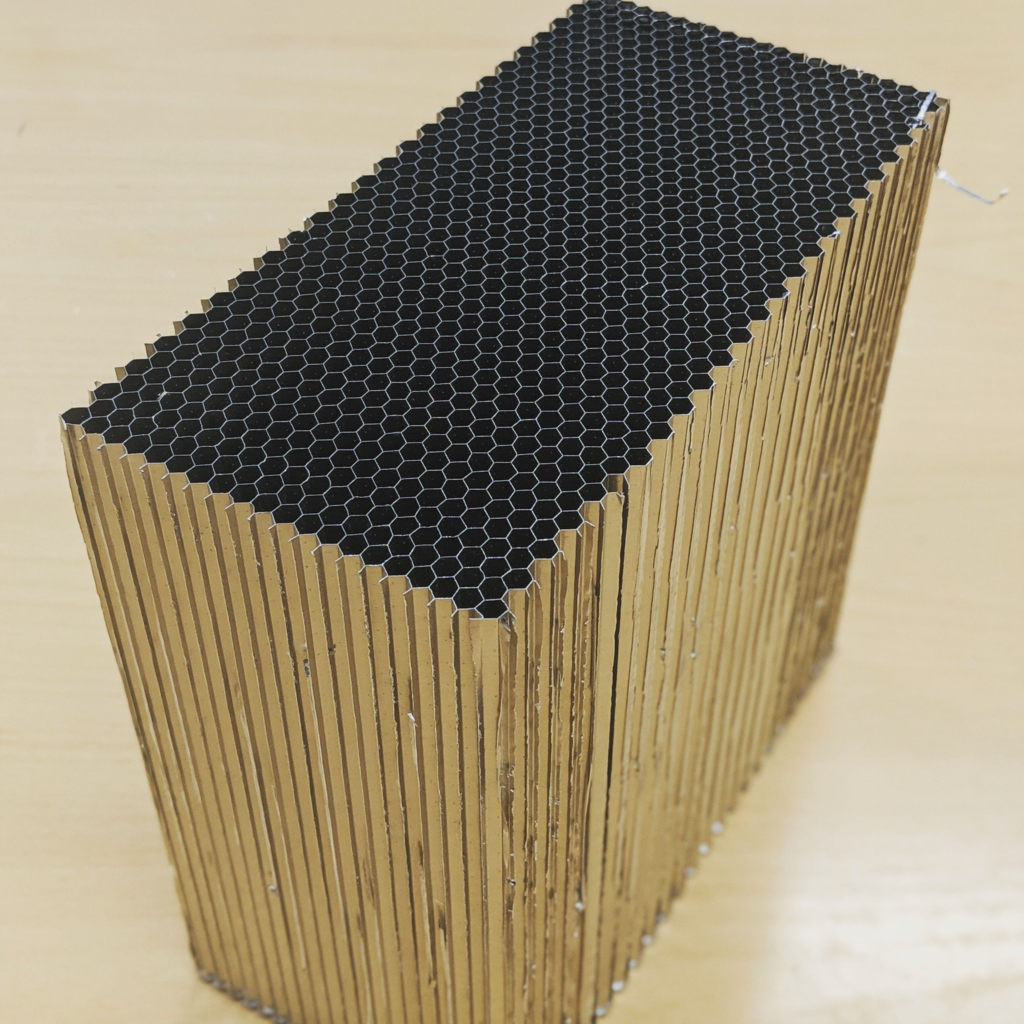

Although this frame did become somewhat heavy from the extra frame members required to house the team’s dual-battery system, it was extraordinarily rigid which allowed the suspension team to precisely tune their setup. As well, its ability to accommodate this unique battery was rewarded by the design judges; helping the car place in the top third of teams in the design event in TAMU’s first year competing in this category.

Learnings

With this being my first major collegiate design project, it is nearly impossible to summarize the amount of hands-on engineering knowledge I gained from this experience. Beyond all the engineering drawings, fastener types, and manufacturing processes, I learned something much deeper from this design: how to manage an engineering project in the real world. With no rubric or answer key to fall back on, me and my team had to decide what the best answers were for ourselves and be confident enough to follow through with them.